Take into consideration an apparel manufacturing facility the place garment QC and QA inspectors spend an entire bunch of man-hours to measure 1000’s of garments every single day. The possibilities of human errors in that case are immense. The humanoid technique leads to unhealthy prime quality.

Equally take into consideration a denim manufacturing facility that requires to measure 1,000 gadgets daily, then roughly 3,000 minutes of the general garment inspectors are dedicatedly required if per piece takes 3 minutes in end-line QC. This leads to solely two selections – each improve the number of employees involved inside the measuring course of or improve the number of days to conduct the strategy sooner than it goes to the next course of. In every situations, the manufacturing facility should take heavy indirect worth into its account whereas planning for a mission.

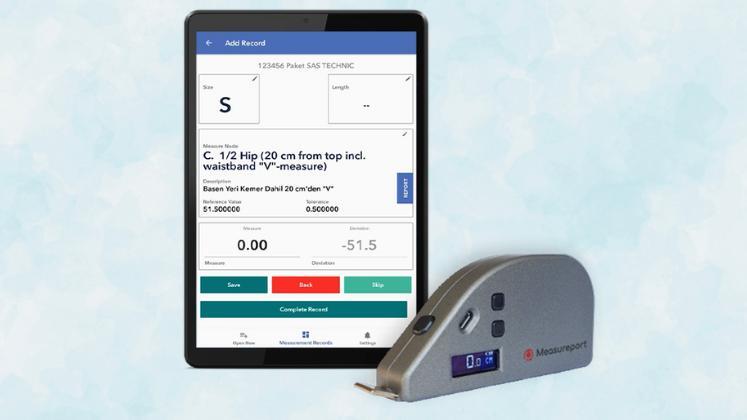

Babylon – primarily based in 2005 and headquartered in California (USA) – represents a imaginative and prescient of innovation inside the measurement processes of denim garments with its ‘Measureport’ system by digitalising the measurement course of.

Standout operate of Measureport

Measureport is a very fast and absolutely mobile-based reply. Its digital measuring tape data every measured parameter and feeds instantly into the app which is displayed on digital screens put in inside the manufacturing facility in real-time. Measureport provides ready-to-use integration devices and a measuring tape. It seamlessly integrates with PLM and ERP features which extra save energy, time and paper.

Measureport saves as a lot as 60 per cent on measurement time and 65 per cent on your entire measuring course of, as per what Group Apparel Sources understood whereas taking a demo of the know-how. The know-how eliminates the need for finding out, calculating deviation and taking notes on any measurements. What’s fascinating is a operate that makes it easy for the administration to recall a rework/rejection and know which operator is answerable for a selected defect so that required movement or teaching initiative can be taken. The experiences can be accessed from wherever inside the globe, using any machine and can be shared with anyone. Every measuring machine is marked with a novel QR code that holds all measurement historic previous.

AR’s Take

There’s no further need to mark down points like ‘Be taught,Calculate’, ‘Bear in mind it down’, ‘Be taught it as soon as extra’, ‘Summarise’. That’s what Group Apparel Sources felt whereas taking a sign of the know-how. We think about Measureport is an excellent machine which removes human error in inspection and permits it to amass experiences in quite a few seconds. It may really save a great deal of hardships on account of man administration and thus contribute positively to the underside line of the company.